Environmental Impacts

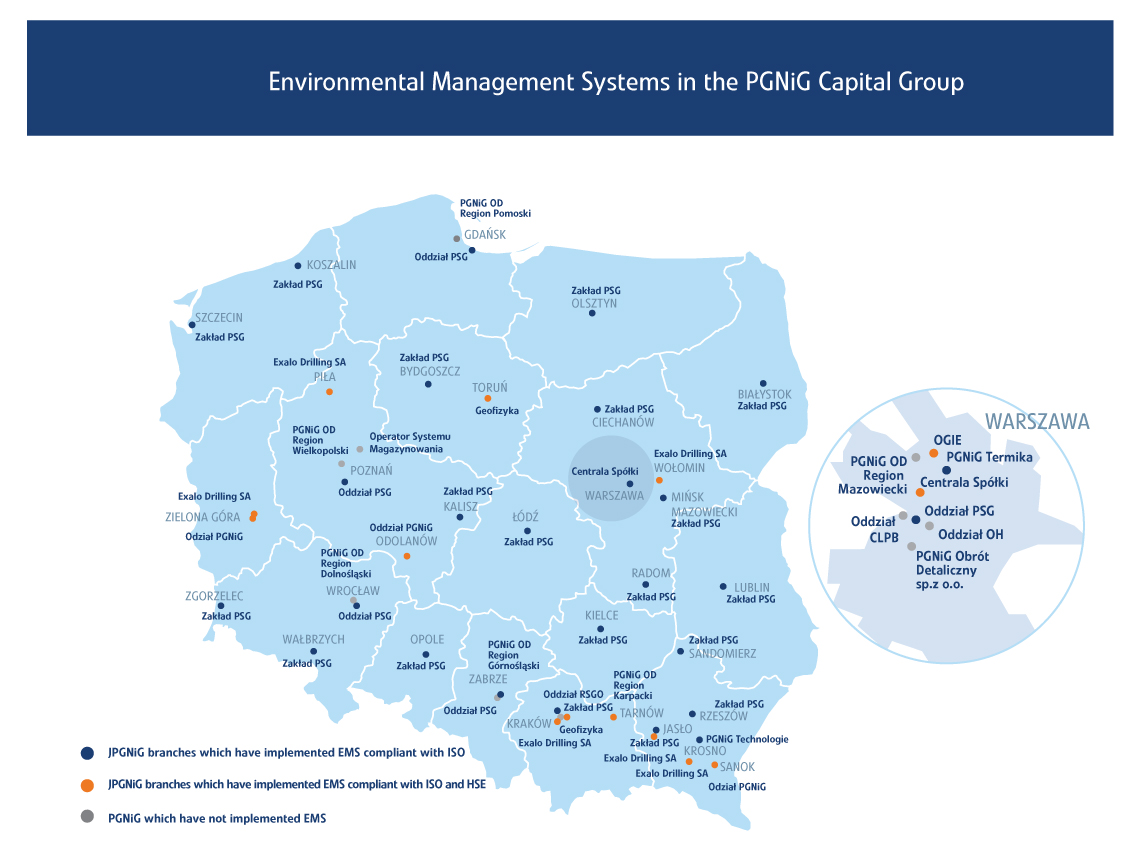

One of the pillars of our Sustainable Development and Corporate Social Responsibility Strategy is that our operations have to be carried out responsibly and with respect for the natural environment. The type of operations conducted by PGNiG Capital Group companies are inevitably associated with environmental challenges. For this reason, one of the Group's key goals in the environmental aspect is to minimize its impact on the natural surroundings.

The PGNiG Capital Group regularly monitors and analyzes the extent of its environmental impacts. Our companies are present on many markets, and the Group's influence spans various environmental aspects. Our impact on the natural environment is particularly felt in two market segments: the mining industry which generates substantial quantities of excavation waste and the power industry which emits pollutants to ambient air.

For more information about our operations in every segment, click here.